-

+8615890068607

+8615890068607

-

+8615890068607

+8615890068607

-

nanbeiinstrument@nanbei-china.com

nanbeiinstrument@nanbei-china.com

Mobile:+86 15890068607

Mobile:+86 15890068607

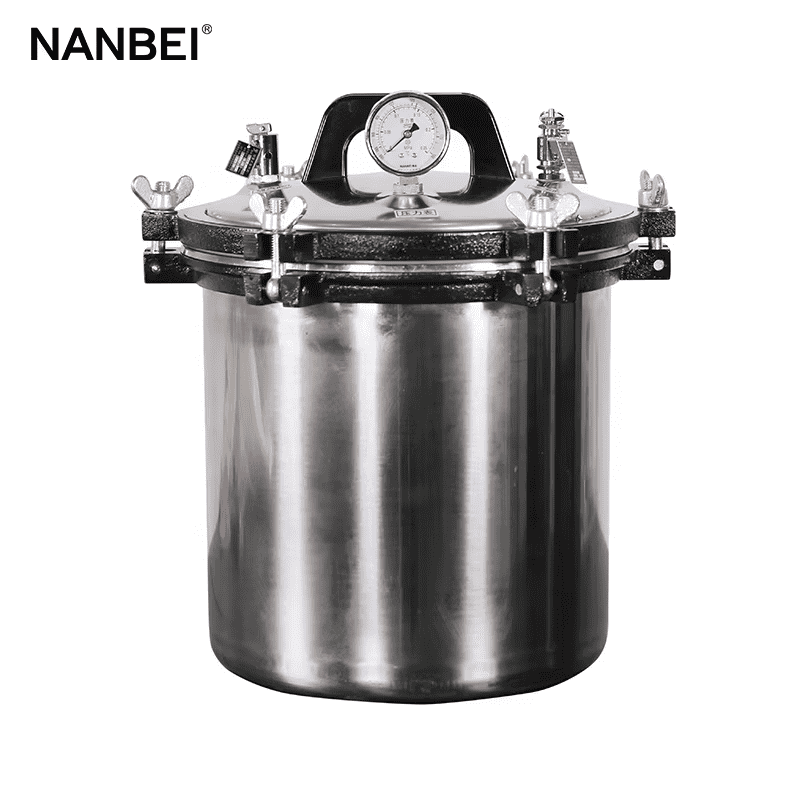

The autoclave is a high-pressure vessel that uses pressure higher than atmospheric pressure to raise the boiling point of water to over 100°C, thereby sterilizing liquids or utensils. Autoclaves are suitable for disinfection and sterilization in medical and health institutions, scientific research and agriculture units etc..

How to troubleshoot heating malfunctions in autoclave sterilizer:

1. Malfunction:

When using the autoclave, the heating function malfunctions, preventing the generation of steam. During operation, the heating indicator light on the panel illuminates, but the temperature does not rise, and the autoclave remains at room temperature.

2. Troubleshooting:

Disconnect the wires connected to the heating element and use a multimeter to check the resistance of the heating element. If the resistance is too high, it indicates an internal open circuit in the heating element, requiring replacement. Since there are reasons for the heating element to burn out in an autoclave, regardless of whether the heating element itself is faulty, the solid-state relay controlling the heating element should be checked. With the autoclave powered on, if the input is normal but the output is abnormal, this relay must be replaced. If the input is abnormal, the load output control section of the control circuit must be checked.

High-pressure steam sterilizers are equipment that use saturated pressure steam to quickly and reliably disinfect and sterilize items. They are classified according to style and size into portable high-pressure steam sterilizers, vertical high-pressure steam sterilizers, and horizontal high-pressure steam sterilizers.

Previous: No Information