-

+8615890068607

+8615890068607

-

+8615890068607

+8615890068607

-

nanbeiinstrument@nanbei-china.com

nanbeiinstrument@nanbei-china.com

Mobile:+86 15890068607

Mobile:+86 15890068607

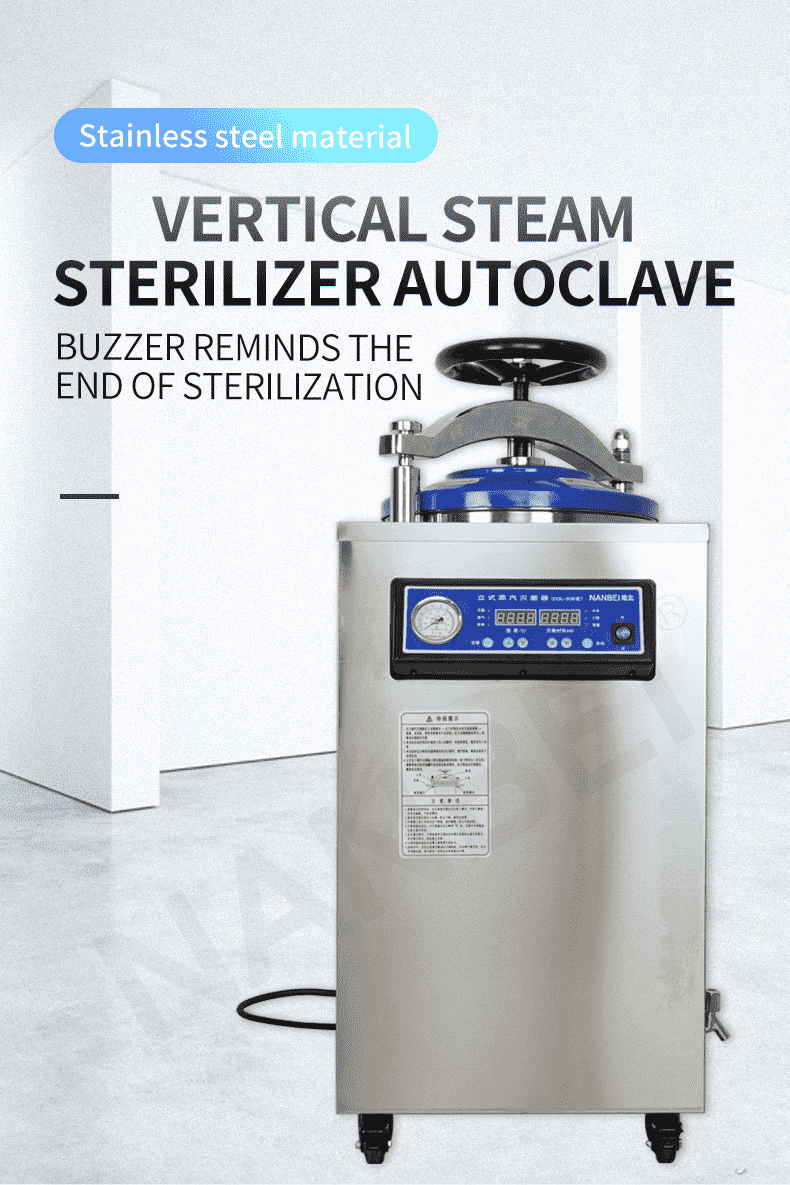

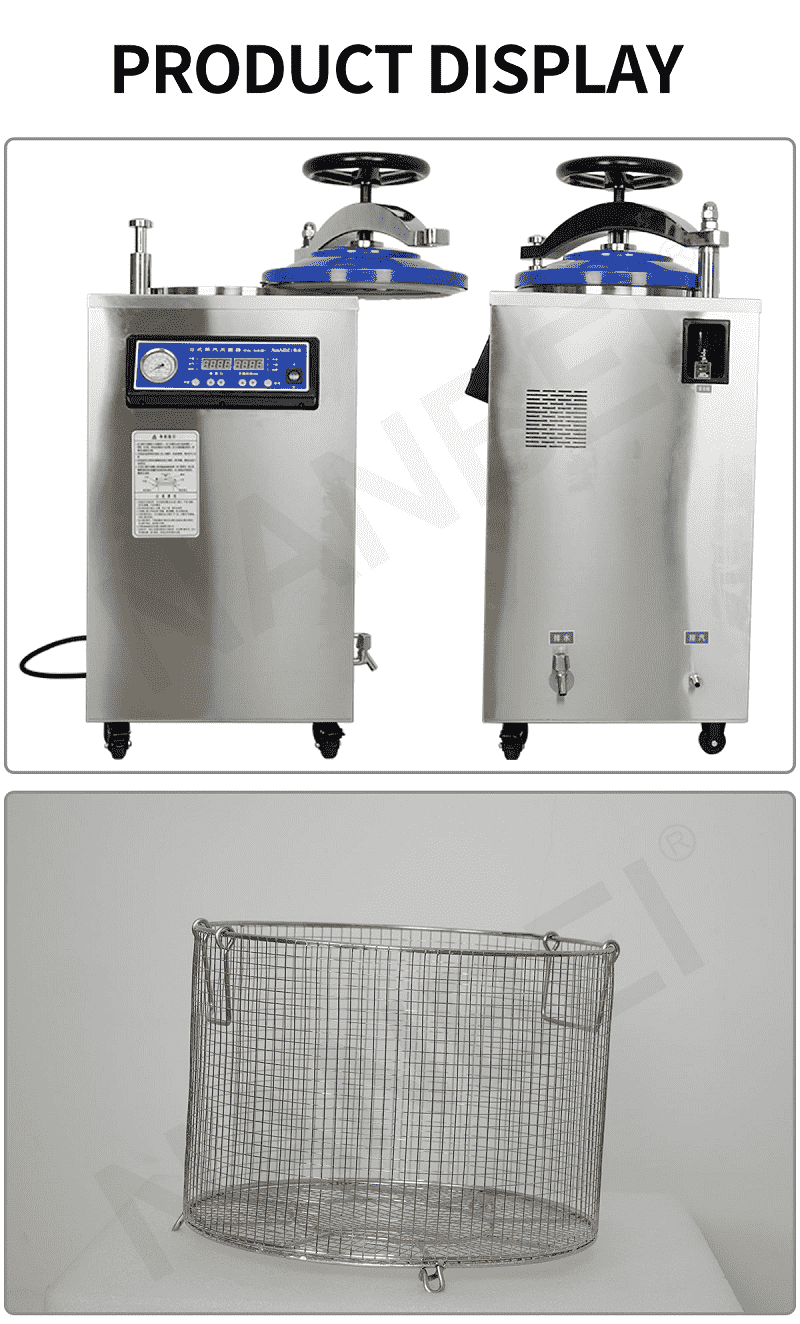

Steam sterilizer is a kind of equipment commonly used in laboratories and medical institutions, and is widely used for disinfection and sterilization of instruments and materials. In order to ensure the sterilization effect, temperature calibration is particularly important.

Temperature calibration refers to the inspection and adjustment of the temperature measurement system of the equipment to ensure the accuracy and reliability of its measurement results. For pressure steam sterilizer, temperature is one of the key factors affecting the sterilization effect.

The calibration process can be divided into the following steps:

1. Preparation: Before temperature calibration, first confirm the normal operation status of the steam sterilizer and prepare the standard thermometer. The standard thermometer should be calibrated and within the valid calibration cycle.

2. Select the measurement point: When performing temperature calibration, a representative measurement point inside the steam sterilizer should be selected. Normally, the measurement point should be located in the center of the sterilization chamber, avoiding proximity to heating elements or cooling devices.

3. Set the temperature: According to the use requirements of the sterilizer, set the equipment to a specific temperature and maintain it for a period of time to ensure that the temperature is stable.

4. Take measurements: Use the standard thermometer to measure the temperature at the selected measuring point and record the results.

5. Compare the results: Compare the reading of the standard thermometer with the temperature display of the sterilizer to determine whether there is a deviation. If there is a significant deviation, adjustments need to be made.

Previous: No Information

How to maintain the performance of pressure steam sterilizer